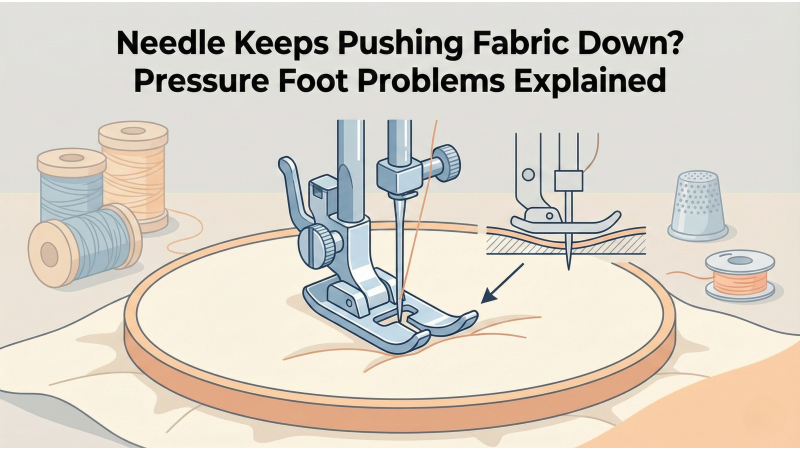

Needle Keeps Pushing Fabric Down? Pressure Foot Problems Explained

When your embroidery machine needle shoves the fabric downward instead of stitching through it, the whole design begins to unravel into little chaos-vortices of thread. This issue affects beginners and professionals alike, and it almost always comes back to presser foot height, hooping tension, stabilizer choice, or needle setup.

Below is a fully expanded guide with practical fixes — and natural interlinks to helpful tutorials, videos, and troubleshooting articles that deepen your understanding of each problem.

Why the Fabric Gets Pushed Down

The needle must enter the fabric with the quiet certainty of a well-guided arrow. When the presser foot floats too far above the surface, or the fabric shifts in the hoop, the fabric falls away from the needle instead of resisting it. This creates dips, distortion, birdnesting, and broken stitches.

- Presser foot height set too high

- Poor hoop tension or slipping fabric

- Incorrect or damaged needle

- Weak or incompatible stabilizer

- Stretchy material with little structure

- Incorrect presser foot pressure

1. Check Presser Foot Height

If the presser foot stands too tall, the fabric doesn't receive the support it needs. Lowering the height (or increasing pressure, depending on the machine) allows the needle to strike cleanly.

For a visual walkthrough, this detailed video demonstration shows how presser foot adjustments affect stitch quality.

2. Ensure the Fabric Is Hooped Firmly

Loose hooping is the hidden saboteur in most embroidery issues. If the fabric is not tightened like a steady drum skin, the needle will push it down with every stroke.

For deeper hooping mastery, this guide on hoop screw tension explains how micro-adjustments keep fabric stable from start to finish.

When hooping still doesn't solve dips, check whether the fabric is flagging — rising and falling with each needle strike — a problem well explained in this flagging troubleshooting guide.

3. Choose the Correct Needle Type

The wrong needle can bruise the fabric instead of slipping through its weave. Wovens prefer sharp needles; knits require ballpoint. A bent or dull needle punches downwards, dragging fabric along with it.

For needle selection clarity, refer to the professional needle guide PDF or browse the organized needle types at Madeira’s needle catalog.

4. Use Proper Stabilizer for the Fabric Type

Stabilizer forms the “floor” beneath your embroidery. If that foundation buckles, the needle’s downward force wins.

- Tear-away for sturdy woven fabrics

- Cut-away for knits and stretchy fabrics

- Water-soluble topper for towels, fleece, or fluff-heavy surfaces

Two layers often help when the fabric is lightweight or prone to shifting.

5. Reduce Machine Speed

High stitching speed can cause the fabric to lift, bounce, or dip. Slowing the pace gives the machine time to form stable, controlled stitches — a simple fix with outsized impact.

6. Adjust Presser Foot Pressure

Some embroidery machines allow pressure adjustments independent of foot height. Low pressure lets the fabric roam; high pressure keeps it grounded.

Experiment slowly: thin fabrics need stronger pressure, while thick materials prefer lighter touch. This concept is also clearly illustrated in this presser foot explanation video.

7. Make Sure the Hoop Is Compatible and Stable

A mismatched or unstable hoop rattles like a loose lid, allowing fabric movement and needle-pushing. Always use hoops designed for your specific machine model.

If you struggle with hoop slippage leading to birdnesting, these troubleshooting ideas from Colman & Company’s birdnesting guide offer helpful clarity.

8. Check for Free-Motion or Darning Foot Mode

Many machines lift the presser foot higher for free-motion quilting. If you accidentally activate this mode, the fabric will jump and sink unpredictably.

A quick reset to embroidery mode usually solves it. If you’re unsure what this mode looks like, this free-motion example video gives a clear reference point.

Additional Helpful Training Resources

If you want a clearer visual sense of how fabric behavior changes under the needle, this fabric-handling breakdown offers a practical demonstration from an embroidery instructor.

When to Seek Professional Help

If the fabric still sinks even after correcting hoop tension, stabilizer, needle type, and presser foot settings, the issue may be mechanical. Internal timing shifts or presser foot bar calibration can cause persistent downward pushing.

In those cases, technicians can realign the presser bar and recalibrate stitch timing — the kind of work briefly shown in this close-up timing video.

Final Thoughts

Most instances of the needle forcing fabric downward come from simple, fixable issues: hoop tension, stabilizer strength, needle type, and presser foot settings. Once those are aligned, your embroidery machine will stitch cleanly — no fabric dips, no birdnesting spirals, no misshapen outlines.

And if you ever want a calm, technical refresher on pressure foot mechanics, this final tutorial clip wraps the essential principles into a useful visual lesson.

Leave a comment