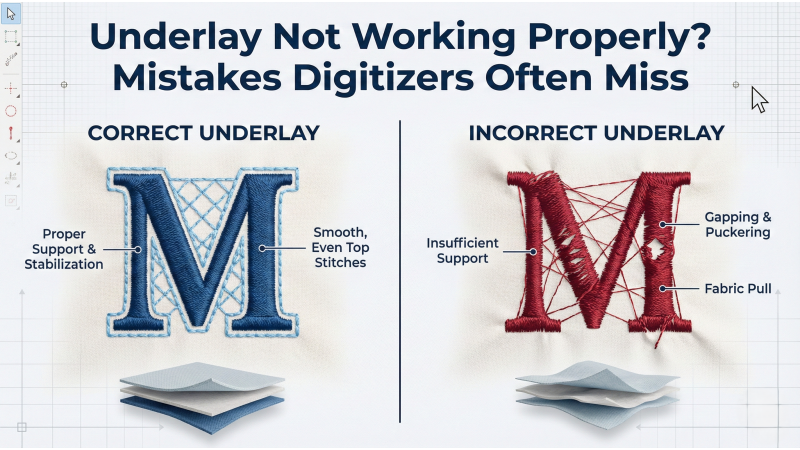

Underlay Not Working Properly? Mistakes Digitizers Often Miss

Underlay is the quiet architecture beneath every clean embroidery design — the hidden beams and supports that keep the top stitches standing proud. When it’s weak, misplaced, or poorly planned, the visible embroidery collapses like a soft roof after heavy rain. Lines wobble, satin columns shift, fill patterns ripple, and lettering loses its bite.

This expanded guide unpacks the subtle underlay mistakes digitizers often overlook, strengthened with essential references like Wilcom’s run underlay settings, Wilcom’s zigzag underlay guide, DigitizingUSA’s small lettering guide, Ignition Drawing’s lettering article, DigitizeAreUs on underlay & backing, and demonstration-rich videos like this underlay breakdown, this troubleshooting example, and this stabilizer-focused lesson.

1. Using the Wrong Underlay Type for the Fabric

Fabrics have personalities — some calm and obedient, others stretchy, textured, or unpredictable. Using a mismatched underlay type is one of the quickest ways to ruin an otherwise good design.

- Cut-away fabrics: Edge run + zigzag adds stability and loft

- Stretchy materials: Strong edge run + dense zigzag prevents distortion

- Caps / structured fabrics: Often need lighter underlay due to built-in firmness

Resources like this underlay & backing guide offer deeper breakdowns of fabric behavior and pairing strategies.

2. Missing an Edge Run Before Satin or Fill Stitches

The edge run is the quiet “outline” stitch that locks the boundary before anything decorative happens. Without it, satin columns spread and fill stitches shift like sand.

Professional digitizers nearly always include an edge run for shapes that need crisp borders.

3. Zigzag Underlay Density Set Too Low

Zigzag underlay adds cushioning — a soft, structured bed for the top thread. If it’s too light, the visible stitches flatten and behave unpredictably. Wilcom’s detailed notes on zigzag structure in their zigzag underlay reference are especially useful when tuning density.

This is critical for micro-satin work and especially for tiny text, a topic explored surgically in DigitizingUSA’s small lettering article.

4. Underlay Not Sized Correctly

Underlay should usually extend slightly beyond the top stitching. Too narrow and it fails; too wide and it peeks out.

Typical offsets hover around 0.2 mm to 0.5 mm, adjusting for density, fabric, and stitch type.

5. Wrong Stitch Angle in Underlay

Underlay isn’t just a support layer — it’s a directional stabilizer. When the underlay angle matches the top-stitch angle, both layers push in the same direction, causing distortion.

Most digitizers aim for underlay angles perpendicular or diagonally opposed to the top layer for maximum brace.

6. Underlay Too Short for Small Letters

Embroidery under 6 mm requires monk-like precision. If the edge run or zigzag underlay is too big, too loose, or missing, small letters collapse into blobs.

Both Ignition Drawing’s small lettering guide and this deeper lettering analysis discuss ideal underlay strategies for micro-text.

7. Speed Too Fast for Weak Underlay

Even well-planned underlay can’t withstand reckless machine speed. Fast stitching stretches fabric, shifts outlines, and causes underlay to lose its stabilizing power.

Lowering machine speed by 10–20% often transforms results instantly.

8. Poor Stabilizer Selection Resulting in Ineffective Underlay

When stabilizer is too thin, soft, or unstable, even perfect underlay falls apart. Choosing the right backing is half the battle.

Heavier backing is recommended for:

- Performance wear

- Stretch-heavy garments

- Large fill areas

A deeper discussion of stabilizer layering is found in DigitizeAreUs’ underlay & backing guide.

9. No Compensation for Fabric Thickness

Thick garments — hoodies, fleece, terry — swallow stitches unless the underlay is reinforced. Extra zigzag density or stronger edge runs are needed to lift the top stitching away from the nap.

Seeing this tested in real time is helpful, which is where tutorials like this stabilizer experiment video become invaluable.

10. Learning From Real-World Digitizing Failures

Hands-on observation teaches faster than any setting table. Creators frequently demonstrate underlay behavior — what collapses, what holds, what shifts with different fabrics.

You can watch underlay changes demonstrated in videos like this underlay walkthrough and this practical test comparison.

Conclusion

Underlay is the structural backbone of embroidery. When its type, density, offset, angle, or stitch logic is off, the top layer betrays it instantly. By understanding these subtle but high-impact mistakes, you gain the ability to produce cleaner edges, stronger fills, crisper lettering, and more stable designs across all fabrics.

Use underlay as a thoughtful foundation — not an afterthought — and your embroidery will reward you with clarity, consistency, and durability.

Leave a comment